2026 Best Stainless Steel Woven Wire Mesh Applications and Benefits?

The demand for stainless steel woven wire mesh is growing rapidly across various industries. According to a recent report by MarketsandMarkets, the global stainless steel mesh market is projected to reach $1.3 billion by 2026. This growth reflects its diverse applications, including filtration, construction, and food processing.

Industry expert Dr. James Lin notes, “stainless steel woven wire mesh offers unmatched durability and corrosion resistance.” This resilience makes it ideal for environments that demand stringent hygiene standards, such as pharmaceuticals and food services. However, some may overlook cost-effectiveness when selecting materials. Investing in higher-quality stainless steel woven wire mesh often proves more economical in the long term.

Despite its many advantages, there are challenges in implementation. Sourcing quality materials can be tricky, and not all suppliers meet industry standards. It's critical for companies to evaluate their needs thoroughly. Only then can they select the most suitable stainless steel woven wire mesh for their specific applications.

Overview of Stainless Steel Woven Wire Mesh

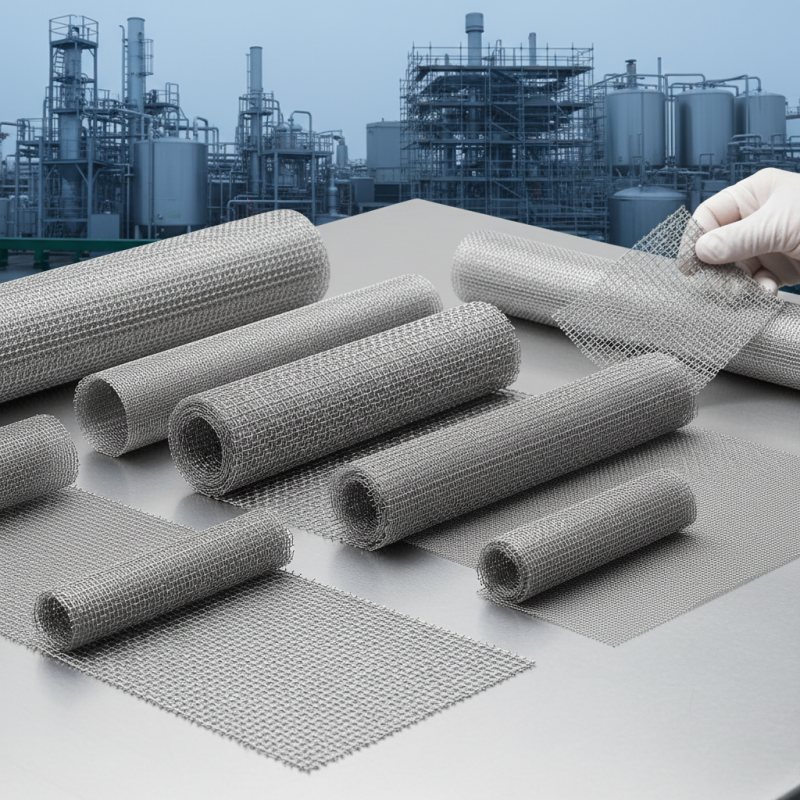

Stainless steel woven wire mesh is widely used across various industries. Its unique properties make it an ideal choice for many applications. The mesh is strong, durable, and resistant to corrosion, making it suitable for indoor and outdoor uses. Common applications include filters, screens, and safety barriers.

When selecting stainless steel woven wire mesh, consider the mesh's aperture size. A finer mesh can filter smaller particles. However, a coarser mesh allows for better airflow and visibility. Each option has its place in design. A balance between functionality and aesthetics is key.

Tips: Regular maintenance of the mesh is essential. Rinse it periodically to prevent dirt build-up. This simple step can prolong its lifespan. Furthermore, ensure that your choice aligns with project needs. Compromising on quality could lead to performance issues later on.

Key Applications of Stainless Steel Woven Wire Mesh in Various Industries

Stainless steel woven wire mesh plays a crucial role in various industries. Its durability and resistance to corrosion make it an ideal choice for filtration, safety, and support structures. According to a recent industry report, the global market for stainless steel woven wire mesh is expected to grow by 5% annually, driven by increased demand in sectors like food processing and pharmaceuticals.

In the food processing industry, it is commonly used for strainers and filters. The mesh ensures that contaminants are removed during production. It can withstand high temperatures and sterilization processes, making it essential for hygienic operations. In the construction sector, stainless steel woven wire mesh supports concrete structures. The mesh provides strength while reducing weight, an essential consideration in modern architecture.

However, not all applications meet expectations. Some users report challenges with mesh size selection. A mesh that is too fine can clog easily, while a coarse mesh may not filter effectively. Sourcing quality materials is also a concern. In regions with less stringent regulations, the quality may vary. These factors highlight the need for careful evaluation and testing before implementation.

Applications of Stainless Steel Woven Wire Mesh in Various Industries

This bar chart illustrates the key applications of stainless steel woven wire mesh across different industries, highlighting its versatility and common uses.

Advantages of Using Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh is increasingly popular across various industries. Its strength and durability make it ideal for demanding applications. Unlike other materials, stainless steel resists corrosion, making it suitable for outdoor and indoor use. This mesh can withstand harsh conditions without degrading.

One significant advantage is its flexibility. It can be woven in different patterns and sizes. This customization fits numerous projects. It is often used in filtration and sieving. The mesh allows for efficient flow while trapping unwanted particles. Additionally, it is easy to clean, enhancing its usability in many scenarios, like food processing.

However, not all applications yield the best results. Sometimes, the mesh may not perform as expected in extreme situations. Users might need to consider the specific environment. If not approached carefully, this can lead to premature wear or breakage. Overall, stainless steel woven wire mesh offers numerous benefits, but users should not overlook potential challenges.

2026 Best Stainless Steel Woven Wire Mesh Applications and Benefits

| Application | Benefits |

|---|---|

| Food Processing | Corrosion resistance, easy to clean, maintains hygiene. |

| Mining and Quarrying | High strength, durability, long service life in harsh environments. |

| Pharmaceuticals | Meets strict cleanliness demands, versatile for various processes. |

| Architectural Applications | Aesthetic appeal, customizable designs, and enhanced durability. |

| Agriculture | Effective for filtering and protecting crops, long-lasting in outdoor use. |

| Automotive | Lightweight, strong, corrosion resistance enhances vehicle longevity. |

| Filtration Systems | High filtration efficiency, resistant to various chemicals. |

Factors to Consider When Choosing Stainless Steel Woven Wire Mesh

When choosing stainless steel woven wire mesh, several key factors come into play. Material quality is crucial. High-grade stainless steel offers enhanced durability and resistance to corrosion. It’s important to assess the specific environment where the mesh will be used. If exposure to harsh elements is expected, opting for a thicker wire might be necessary.

Additionally, consider the mesh's opening size. Smaller openings can prevent debris from passing through but may restrict airflow. On the other hand, larger openings promote better ventilation. Reflect on the application’s demands. You need the right balance between strength and functionality. Compatibility with other materials is another aspect to think about. Ensure the chosen wire mesh fits seamlessly into your project.

Lastly, weave type plays a significant role. A tighter weave can enhance strength but could increase the cost. It’s essential to weigh the benefits against potential budget constraints. Keep in mind that perfection is rarely achievable. Regular evaluations of the chosen mesh's performance might reveal areas for improvement.

Future Trends in Stainless Steel Woven Wire Mesh Applications and Technology

The future of stainless steel woven wire mesh applications looks promising. With ongoing advancements in technology, its uses are expanding rapidly. Industries such as construction, filtration, and agriculture are increasingly turning to this durable material. Its resistance to corrosion and high strength make it an ideal choice for various applications.

One notable trend is the customization of wire mesh. Manufacturers are now able to create specific mesh sizes and shapes to meet unique client needs. This capability allows for more efficient designs and better performance in specific tasks. However, this shift also raises questions about standardization. Custom solutions may lead to inconsistency across industries, as different specifications emerge.

Another area of focus is sustainability. As awareness of environmental issues grows, many are seeking eco-friendly solutions. Stainless steel is recyclable and has a long lifespan, which is beneficial. Yet, extracting and processing it still has a carbon footprint. It’s crucial to balance innovation with ecological responsibility. How can manufacturers minimize environmental impact while enhancing performance? This remains a challenging yet important question in the evolution of stainless steel woven wire mesh applications.