What is Stainless Steel Wire Mesh and Its Uses?

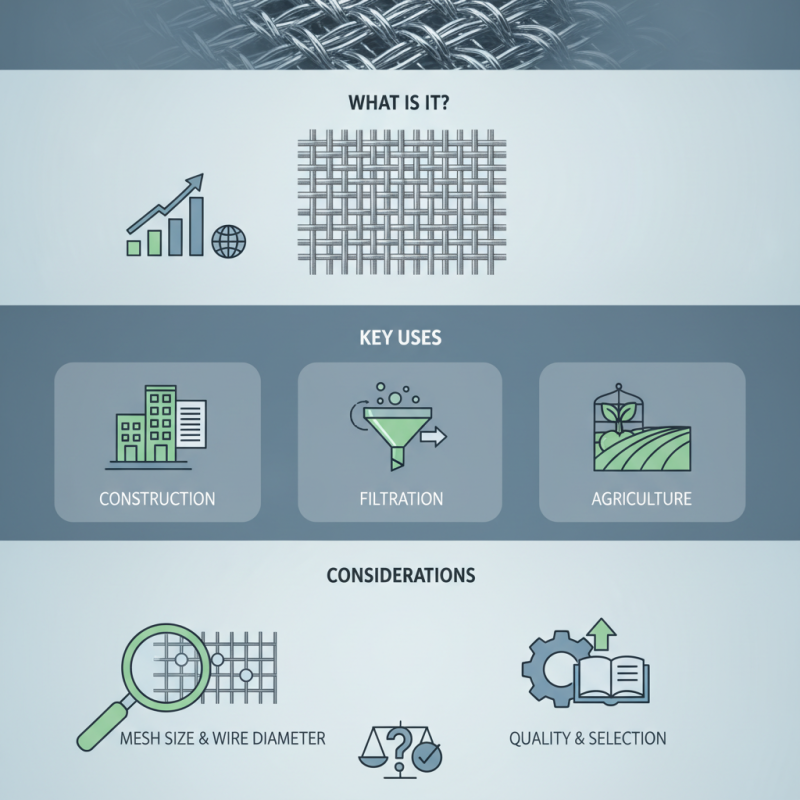

stainless steel wire mesh is more than just a material. It serves many purposes across various industries. According to industry reports, the global stainless steel mesh market is projected to reach USD 1.35 billion by 2027, growing at a CAGR of 4.5%. This growth highlights its extensive applications and versatility.

stainless steel wire mesh is used in construction, filtration, and even agriculture. In construction, it provides strength and durability. In filtration systems, it ensures precise sorting and separation. However, the complexity of ensuring quality and consistency often presents challenges.

Despite its advantages, stainless steel wire mesh requires careful selection for optimal results. Factors like mesh size and wire diameter greatly affect performance. Users may overlook these details, leading to unsatisfactory outcomes. To maximize its potential, deeper industry knowledge is essential.

What is Stainless Steel Wire Mesh?

Stainless steel wire mesh is a versatile material used in various applications. It consists of stainless steel wires woven together. The mesh can come in different sizes and thicknesses. This makes it adaptable for numerous projects. The stainless steel offers durability and resistance to corrosion. These properties make the mesh highly valued in many industries.

In construction, stainless steel wire mesh is often used for reinforcement. It can be found in walls, ceilings, and floors. Its strength helps structures endure heavy loads. In food processing, it is used to create filters and strainers, ensuring product purity. However, mesh can sometimes be unsuitable for certain high-stress situations. Creative uses, such as decorative elements or as partitioning, can lead to unexpected challenges. Adjustments might be necessary to meet specific project goals.

Understanding the characteristics of stainless steel wire mesh can improve its application. It is essential to consider the environment where it will be used. Not every gauge will work in every setting. Testing various types may lead to better outcomes. Ultimately, being aware of its limitations can help avoid costly mistakes.

Types of Stainless Steel Wire Mesh and Their Characteristics

Stainless steel wire mesh comes in various types, each serving unique purposes. For instance, 304 stainless steel mesh is one of the most popular choices. It offers excellent corrosion resistance and is commonly used in kitchens and food processing. The mesh can prevent smaller particles from passing through while allowing air circulation.

Another type is 316 stainless steel mesh, known for its durability. It’s ideal for marine environments where salt exposure is significant. This mesh type is slightly more expensive but offers better protection against rust. The long-term benefits may outweigh the initial cost if used correctly.

Finally, there’s welded stainless steel mesh. This version is durable and maintains structural integrity. It often finds applications in construction and industrial settings, where strength is crucial. However, the installation process can be mishandled, requiring more attention to detail. Each type of mesh has its characteristics, and understanding these can lead to better decision-making in their applications.

Common Applications of Stainless Steel Wire Mesh

Stainless steel wire mesh is versatile and widely used in various applications. Its durability and resistance to corrosion make it ideal for both indoor and outdoor uses. One common application is in filtration systems. Stainless steel wire mesh effectively filters liquids and gases, ensuring purity in many industries.

Another significant use is in construction. It serves as reinforcement in concrete. The mesh enhances strength, ensuring structures can bear heavy loads. In the agricultural sector, farmers utilize it for fencing. It keeps pests out without harming the animals within.

However, not every use is straightforward. Some users find the mesh challenging to install. It requires precise measurements for effective results. Additionally, improper choices in mesh size can lead to inefficiencies in filtration or reinforcement. Those using the mesh must pay attention to these details.

What is Stainless Steel Wire Mesh and Its Uses? - Common Applications of Stainless Steel Wire Mesh

| Application | Description | Mesh Type | Wire Diameter (mm) |

|---|---|---|---|

| Filtration | Used in various sectors to filter solids from liquids and gases. | Welded | 0.8 |

| Safety Barriers | Commonly used in construction sites and public areas to ensure safety. | Welded | 1.5 |

| Architectural Grilles | Decorative elements for buildings while providing ventilation and light. | Woven | 1.2 |

| Industrial Screens | Used to separate materials in industrial processes. | Woven | 1.0 |

| Animal Inclosures | Providing secure environments for animals in farms and zoos. | Welded | 2.0 |

| Food Processing | Used for cleaning, grading, and packaging of food products. | Woven | 0.5 |

| Garden Fencing | Durable fencing solution for garden protection. | Welded | 1.2 |

Advantages of Using Stainless Steel Wire Mesh

Stainless steel wire mesh is known for its remarkable durability. It resists corrosion, making it suitable for outdoor and industrial applications. This feature ensures it lasts longer, reducing replacement costs over time. Unlike other materials, stainless steel doesn’t rust, even in humid conditions. It is a reliable choice for various projects.

Using stainless steel wire mesh provides strength and versatility. It can be used in filtration systems, animal enclosures, and safety guards. The mesh exists in various sizes and patterns, allowing customization for specific needs. Installers appreciate its ease of use. However, some may struggle with cutting or welding it to fit unique structures.

The aesthetic appeal of stainless steel wire mesh cannot be overlooked. It offers a clean, modern look that blends well with different designs. Some may find the initial cost higher than alternatives. Yet, the long-term benefits usually outweigh this concern. Overall, the use of stainless steel wire mesh is sensible for many applications despite some challenges.

Maintenance and Care for Stainless Steel Wire Mesh Products

Maintaining stainless steel wire mesh products is essential for longevity and durability. Regular cleaning helps remove contaminants. This could include dust, grease, and moisture. The International Wire & Mesh Association suggests routine inspections, noting any signs of wear or corrosion. Even minor imperfections can lead to bigger issues over time.

Tips: Use a mild detergent and soft brush for cleaning. Avoid harsh chemicals, as they may damage the finish.

Ensure the mesh is stored properly when not in use. It should be kept in a dry area to prevent moisture-related issues. The American Society for Testing and Materials highlights that rust can develop if the protective oxide layer is compromised. Regular checks are vital to maintain this layer.

Tips: Consider applying a protective coating for added longevity. Always inspect before using in critical applications.